A single-screw extruder is simpler and more cost-effective for processing simple, homogeneous materials, while a twin-screw extruder uses two intermeshing screws to provide superior mixing, venting, and flexibility for more complex, higher-value materials. Twin-screw extruders offer better performance and consistency, especially with high-viscosity materials or complex formulations, while single-screw extruders are better for higher-volume, basic applications like pipes or film.

Feature | Single-Screw Extruder | Twin-Screw Extruder |

Mechanism | A single, helical screw rotates to convey, melt, and homogenize materials through friction and pressure. | Two intermeshing screws rotate together, allowing for more efficient mixing, conveying, and venting. |

Materials | Best for simple, homogeneous materials like granular polymers. | Ideal for complex formulations, high-viscosity materials, and plastic modification. |

Performance | Sufficient for basic applications; mixing is less intensive. | Superior mixing, kneading, and dispersing capabilities. |

Applications | General extrusion of pipes, tubes, and simple films. | Plastic compounding, foam extrusion, and recycling. |

Cost | Lower initial and maintenance costs. | Higher initial cost but can be justified by superior performance and versatility. |

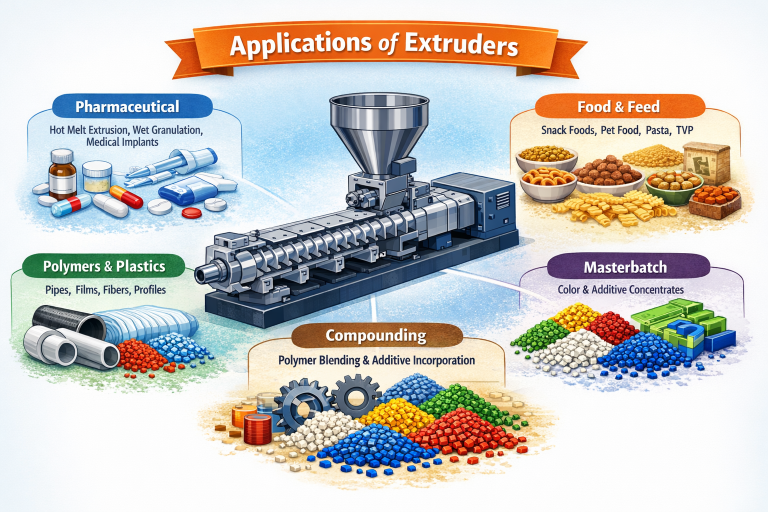

Extruders have diverse applications across multiple industries, playing a crucial role in processing materials through a continuous, controlled shaping process. Key applications span the pharmaceutical, food, polymer, compounding, and masterbatch sectors.

Applications by Industry

Specific Applications | Purpose | |

Hot melt extrusion (HME), wet granulation, spheronization feedstock preparation, implant/device manufacturing | Enhances drug solubility and bioavailability, controlled drug release, shaping medical devices. | |

Cereal production, snack foods, pasta, pet food, modified starches, textured vegetable protein (TVP) | Cooking, shaping, texturizing, expanding, and creating consistent product forms. | |

Pipe/sheet/film extrusion, wire coating, fiber production (filaments), profile extrusion | Continuous shaping of plastic products, insulation for wiring, production of synthetic fibers . | |

Alloying/blending different polymers, incorporating additives (fillers, colorants, stabilizers) | Creating customized plastic materials with specific physical properties tailored for specific uses . | |

Dispersing high concentrations of pigments or additives into a carrier resin | Producing concentrated color or additive pellets that are later diluted during final product manufacturing. |

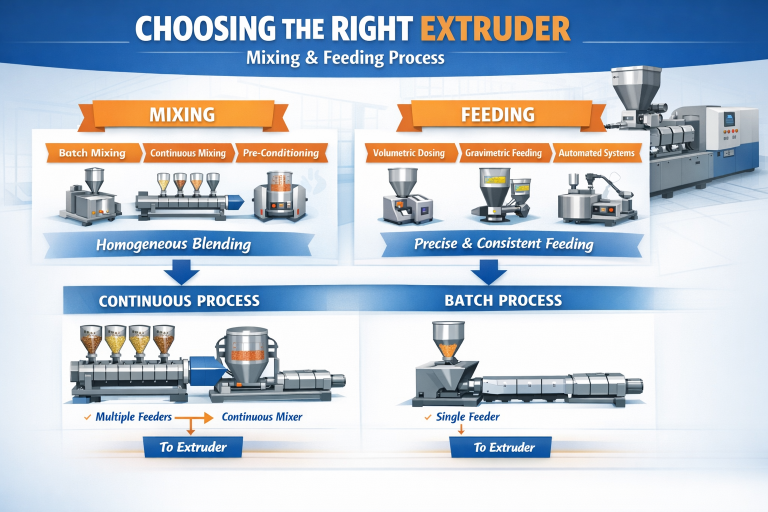

Mixing and feeder to extruder

Mixing and feeding to an extruder involves combining raw materials for consistent quality and then precisely delivering them into the extruder. This process can be done in batches or continuously, with automated gravimetric feeders ensuring accuracy. Pre-mixing and conditioning the materials before they enter the extruder is crucial to prevent inconsistent quality, pressure fluctuations, and product defects.

Purpose: To create a homogeneous mixture of ingredients, as the extruder has limited ability to mix materials. Poor homogeneity can lead to inconsistent final product quality.

Purpose: To provide a continuous and precise flow of the material mixture into the extruder’s inlet.

Importance: Even small fluctuations in the feed rate can cause pressure and output fluctuations, leading to defects like irregular dimensions or bubbles on the product’s surface.

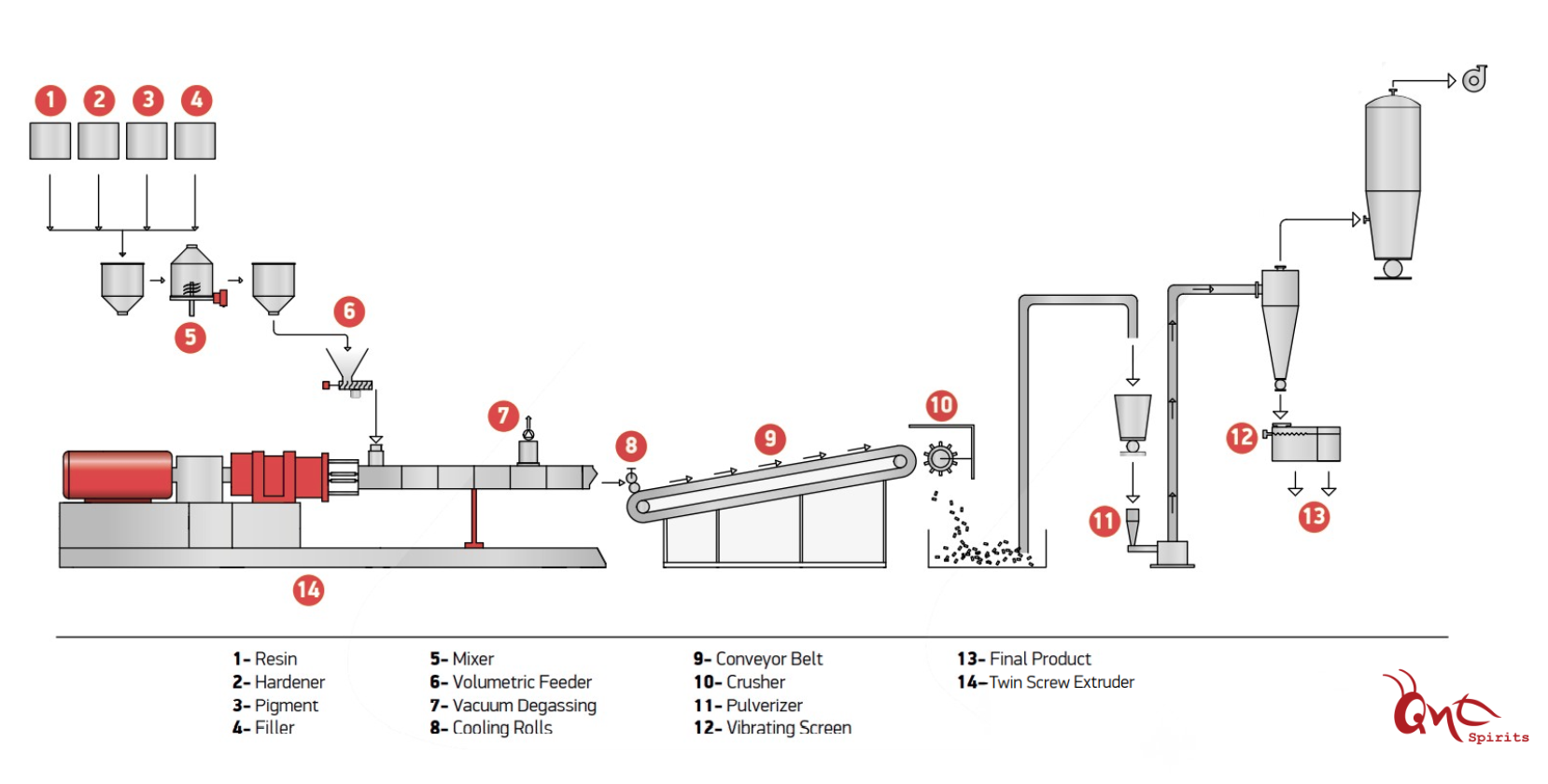

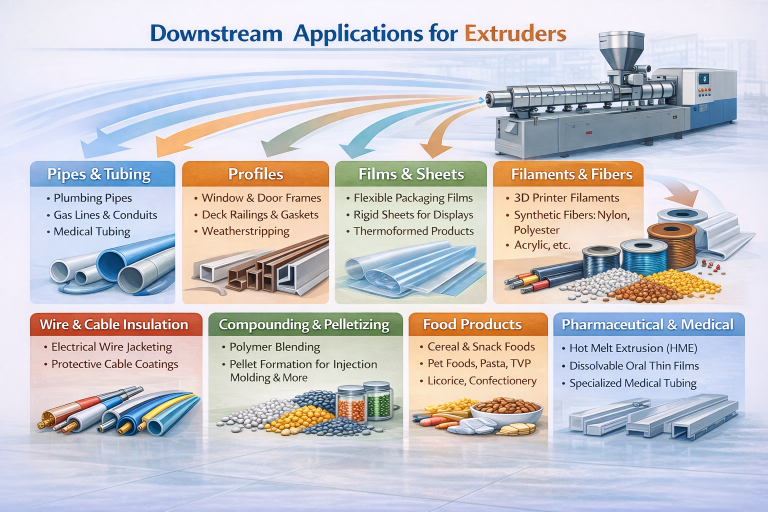

Extrusion is a high-volume manufacturing process used across various industries, and its downstream applications encompass a wide range of continuous products and intermediate materials. The specific application depends heavily on the material being extruded (plastics, metals, rubber, food, pharmaceuticals) and the final desired form.

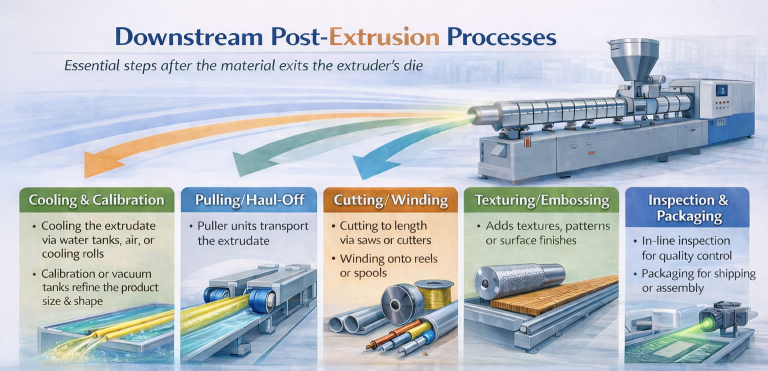

After the material exits the extruder’s die, a series of essential downstream operations take place to form, finish, and prepare the final product:

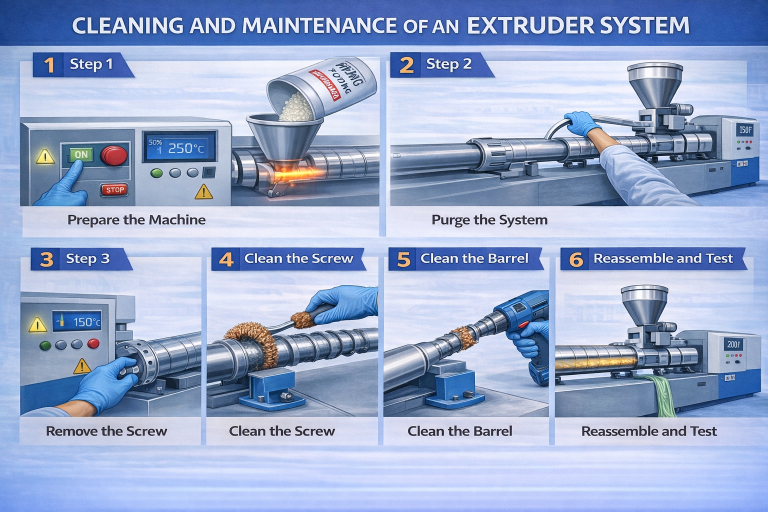

Cleaning an extruder involves purging the machine with a cleaning material and then manually cleaning the screw and barrel. Maintenance includes daily checks of temperatures and noises, weekly checks of oil levels and filters, and monthly/quarterly inspections of wear and tear on components like gears, screws, and motors. Regular maintenance prevents clogs, improves productivity, and extends the life of the machine.

Power on the machine and heat the barrel to the appropriate temperature for the material being purged. Stop the material feed.

Insert a purging compound, such as a cleaning resin, into the hopper and run the extruder until the material exits cleanly.

Lower the barrel temperature to a safe level to allow for handling, but ensure it’s not too low to make the plastic hard and difficult to remove. Remove the die head and, using a tool as a lever, push the screw out of the barrel.

Use a wire brush and scraper to remove excess plastic from the screw flights. For stubborn residue, wrap a piece of copper gauze around a flight and move it back and forth.

Once the screw is out, clean the barrel using the same methods, such as a wire brush attached to a drill with copper gauze, and then wipe it clean with a lint-free cloth.

Reinstall the screw, reattach the die head, and perform a test run to ensure all parts are clean and functioning correctly.